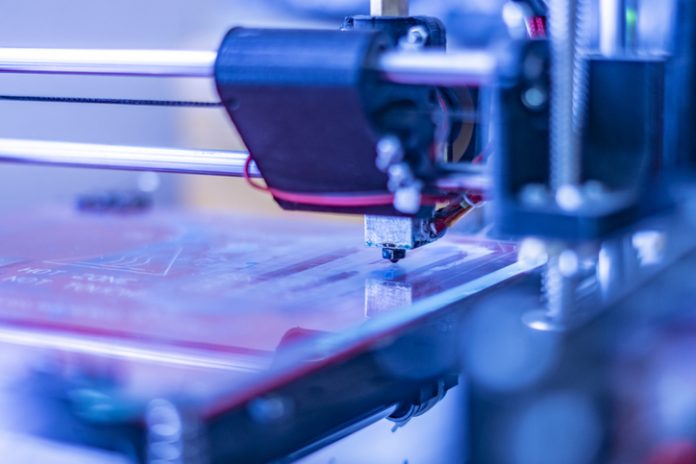

Stereolithography (SLA) 3D printing is the most prevalent resin 3D printing method, and it has grown in popularity due to its capacity to generate high-accuracy, isotropic, and waterproof prototypes and end-use components in a variety of sophisticated materials with precise details and a fine surface texture.

Discover how SLA 3D printers work, why countless pros use them now, and how SLA printers can help you with your job in this detailed tutorial.

What is SLA, and how does it work?

SLA 3D printing is a well-known 3D printing technique for creating graphical prototypes in various sectors. Due to the general exceptionally smooth texture and distinct features obtained from various thermosets, it is garnering prominence over other 3D printing technologies.

SLA cures photopolymer cross-sections and prints 3D objects with a computer-controlled rotating ultraviolet laser beam and CAM/CAD software. In as little as one day, this method can produce conceptual designs, rapid prototypes, and intricate assembling parts with geometric exactness.

A construction platform is dropped into a vat of liquid UV-sensitive polymer, in which the top of the liquid is cured, and a UV laser solidifies a thin unit of the design. The building substrate is lowered one layer until the part is finished.

Arched components are reinforced by support structures, guaranteeing that the model is appropriately linked to the platform. After printing, the model is sanded to eliminate the props and the support markings.

SLA 3D printing services are an excellent alternative for designing patterns, molds, and assembly parts if you need incredibly detailed samples with strict specifications and flawless surfaces. The SLA 3D printing technology is the route for automobiles to jewelry, medicine, schooling, and model creation.

Reason You Should Include SLA in Your Work

The following are some of the advantages of using SLA printing in your design process:

Create accurate, precise parts in a matter of hours

SLA printing is the classic type of 3D printing, and it uses a tiny laser beam as small as 0.05mm to create objects. Because this technology is applied layer by layer, the completed items will have greater precision and exquisite features. SLA printing, on the other hand, is beneficial for creating complicated geometric shapes.

Streamline production operations that may otherwise be time-consuming.

While infusion shaping is a superior choice for making huge parts, it very well may be awkward for one-off model plans. If you’ve been experiencing difficulty meeting timetables with your present assembling tasks, SLA could be the thing you are searching for.

SLA printing ensures speedier form times. On the other hand, it’s the ideal procedure for little assembling runs in light of your execution. There is an assortment of modern tars realistic with magnificent designing characteristics as excessive use.

Create prototypes that can function as the final products

Traditional assembling cycles, for example, infusion shaping, expect you to make a form before progress, which takes some time. You might be depending on a similar cycle for your models too. This postpones your item improvement process thus.

However, as prototyping assumes an essential part in the item improvement process, a phase can’t be compromised. With SLA printing, you can make usable models that capacity as the eventual outcomes, achieved in a short measure of time.