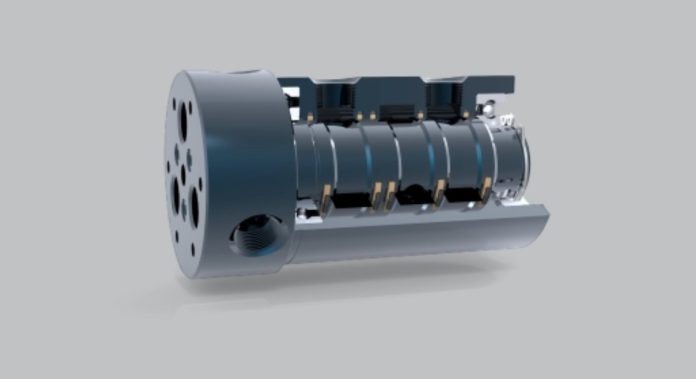

Slip rings are integral components used in various applications to enable the transmission of electrical signals and power between rotating and stationary parts. While traditional slip rings are commonly constructed using metals, ceramic materials have gained popularity, especially in high-temperature environments. The importance of slip rings are made of ceramic materials and their advantages in high temperature applications, article focus.

High-Temperature Resistance: Ceramic materials excel in high-temperature environments. Slip rings made of ceramic can withstand extreme temperatures without compromising their structural integrity or performance. They exhibit excellent thermal stability, allowing them to operate reliably in applications where temperatures can reach several hundred degrees Celsius. This high-temperature resistance makes ceramic slip rings suitable for industries such as aerospace, power generation, and metallurgy.

Electrical Insulation: Ceramic materials possess excellent electrical insulation properties. Slip ring made of ceramic provide effective electrical insulation, preventing the flow of electrical current between conductive components. This insulation property ensures safe and reliable transmission of electrical signals, reducing the risk of short circuits or electrical malfunctions. Ceramic slip rings are particularly advantageous in high-voltage applications or environments with potential electrical hazards.

Chemical Inertness: Ceramics are highly chemically inert materials, meaning they are resistant to the effects of various chemicals, acids, and corrosive substances. Slip rings made of ceramic can withstand exposure to aggressive chemical environments without degradation or corrosion. This chemical inertness makes ceramic slip rings suitable for applications in chemical processing, semiconductor manufacturing, or any environment with corrosive agents.

Low Friction and Wear: Ceramic materials exhibit low friction and wear properties, resulting in reduced mechanical wear and extended lifespan of the slip ring assembly. The smooth and hard surface of ceramic slip rings minimizes friction between rotating and stationary components, leading to lower frictional losses and improved overall efficiency. This characteristic is beneficial in high-speed rotating systems, where friction and wear can impact performance and longevity.

Dielectric Strength: Ceramic slip rings offer high dielectric strength, enabling them to withstand high voltages without breakdown or electrical discharge. This dielectric strength is crucial in applications where insulation integrity is critical, such as in high-voltage power transmission or electrical testing. Ceramic slip rings provide a reliable and safe solution for high-voltage applications due to their excellent dielectric properties.

Low Thermal Expansion: Ceramic materials have low thermal expansion coefficients, meaning they exhibit minimal dimensional changes with temperature variations. Slip rings made of ceramic maintain their shape and dimensions even when subjected to significant temperature fluctuations. This low thermal expansion property ensures consistent performance and avoids potential issues related to dimensional instability in high-temperature environments.

Lightweight and High Strength: Ceramics offer a unique combination of lightweight construction and high strength. Ceramic slip rings provide the advantage of being lightweight, reducing the overall weight of the system and minimizing the strain on rotating components. Despite their lightweight nature, ceramic materials exhibit exceptional strength, allowing slip rings to withstand mechanical stress and vibrations. This lightweight and high-strength characteristic contributes to improved performance and durability.

In conclusion, ceramic slip rings offer significant advantages in high-temperature environments. With their high-temperature resistance, excellent electrical insulation, chemical inertness, low friction and wear, dielectric strength, low thermal expansion, and lightweight high-strength construction, ceramic slip rings provide a reliable solution for demanding applications. From aerospace and power generation to chemical processing and high-voltage systems, ceramic slip rings play a crucial role in ensuring efficient and reliable electrical signal transmission in high-temperature conditions.