Let us introduce you to Pipe Fitting Mould; Pipe fitting moulds are one of the most critical parts of the pipe fitting process. They are responsible for shaping the metal into the correct form to be used in construction projects. There are various molds available, each with its own set of benefits and drawbacks. To make an informed decision about which type of mold is right for your project, it is crucial to understand the basics of each kind.

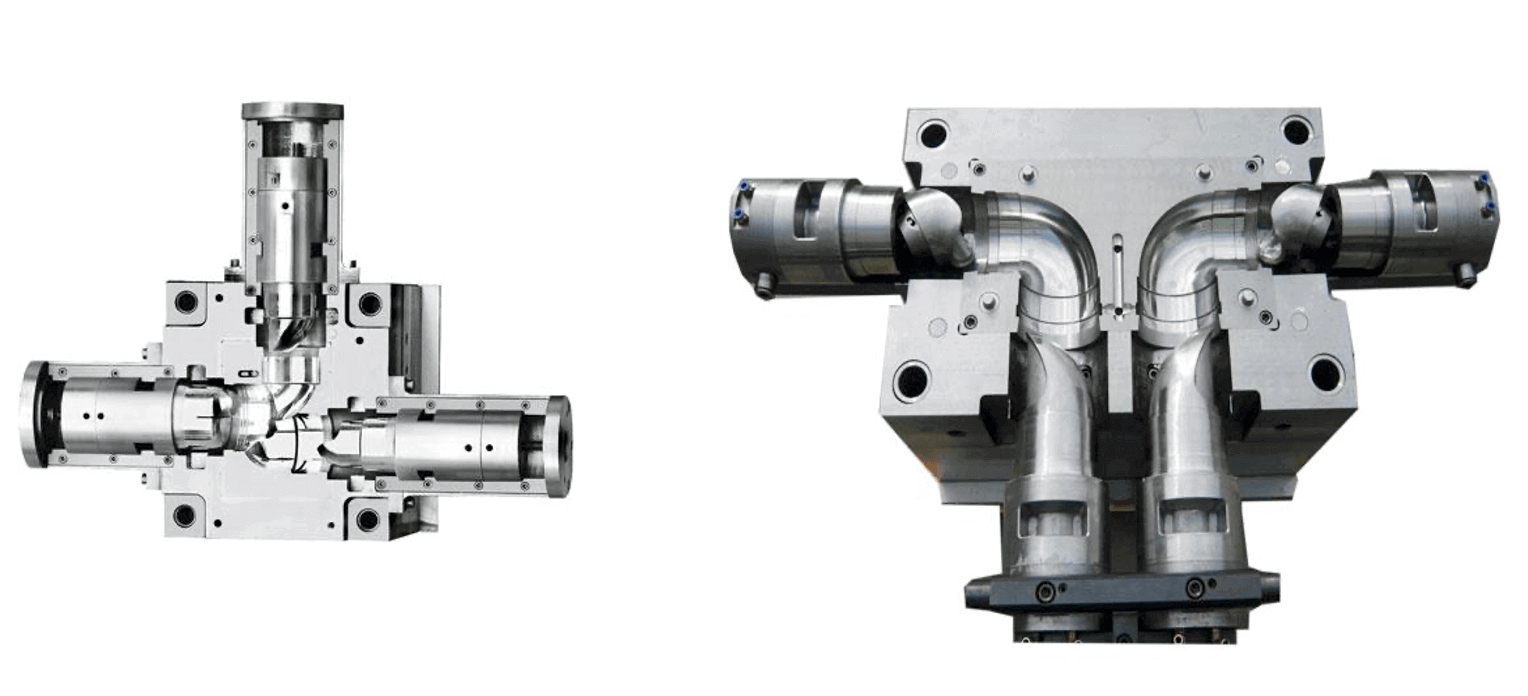

In addition, Pipe fitting moulds fall under three categories: extrusion, die casting and forging. Extrusion moulds are made from various materials, including metals, plastics, and composites. They are typically used to create smaller pipe fittings, such as elbows, tees, and reducers. Die casting moulds are made from metals to generate larger pipe fittings, such as flanges and couplings. Forging moulds are made from metals and are used to create the most common type of pipe fitting.

Each type of mould has its own set of benefits and drawbacks. Extrusion moulds are typically the most affordable option, and they are also very versatile. Die casting moulds are the most durable option, and they can withstand high temperatures and pressures. Forging moulds are the most accurate option, and they produce fittings with the lowest level of defects.

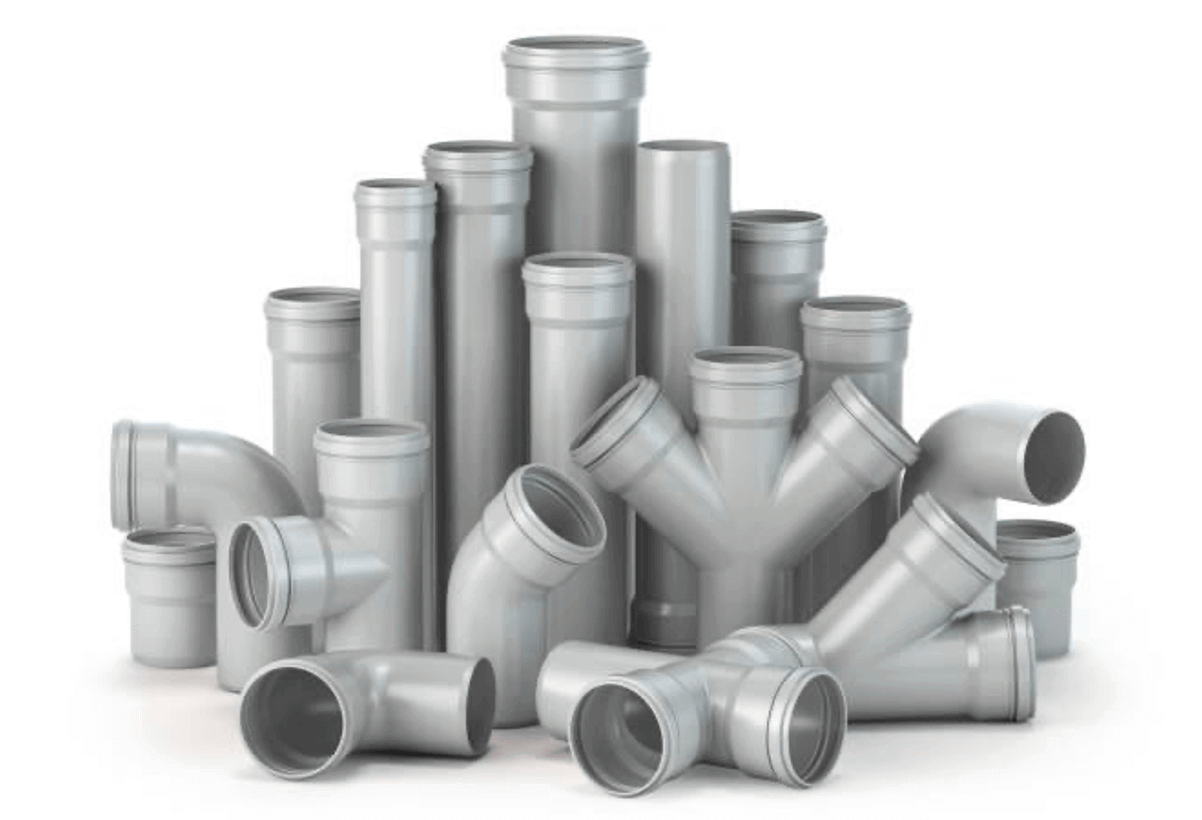

The various varieties of pipe fitting moulds are made to do different jobs. HDPE pipe fitting mould is made to extrude HDPE pipes. PVC pipe fitting mould is used to produce PVC pipes. P trap Mould is used to create a P trap for the drainage system. Whereas, some moulds are made to specifically forge fittings, such as elbow fitting mould, tee fitting mould, and reducer fitting mould. Each of these moulds is designed to create a specific type of fitting.

Abs pipe fitting mould is also one of the significant types of moulds. It is extensively used in water supply systems to join two pipes of different diameters and wall thicknesses. It holds a particular type of flange called an ABS flange. This flange connects the pipe to a fixture, such as a toilet or a faucet.

Considering the comparison of pipe fitting mould with thread fitting mould, the pipe fitting mould is more advantageous. It doesn’t need any extra tool for fixing the pipes into it, and also, there is no limitation of thread size. So, it can be easily used with any size of pipes. Moreover, it is easier to operate and handle.

It is crucial to consider the needs of your project when choosing a pipe fitting mould. The suitable mould will ensure that your pipe fittings are of the highest quality and meet all your needs. With the technology change, pipe fitting moulds are now being made to do more than just one job. This gives you a lot of choices to make when looking for the right one for your project.

Talking about the applications of pipe fitting moulds, they are used in many industries. Some of the most common applications are construction, automotive, and aerospace. In construction, they are used to create water pipes, drainage pipes, and other piping systems. In automotive, they create fuel lines, brake lines, and cooling systems. And in aerospace, they are used to create air conditioning lines, hydraulic lines, and more.

Besides the industries mentioned above, pipe fitting moulds are also used in many other industries. Some of these industries include medical, marine, and agricultural. The medical industry uses them to create medical tubing. The marine industry uses them to produce fuel lines and water lines. The agricultural industry uses them to design irrigation systems.

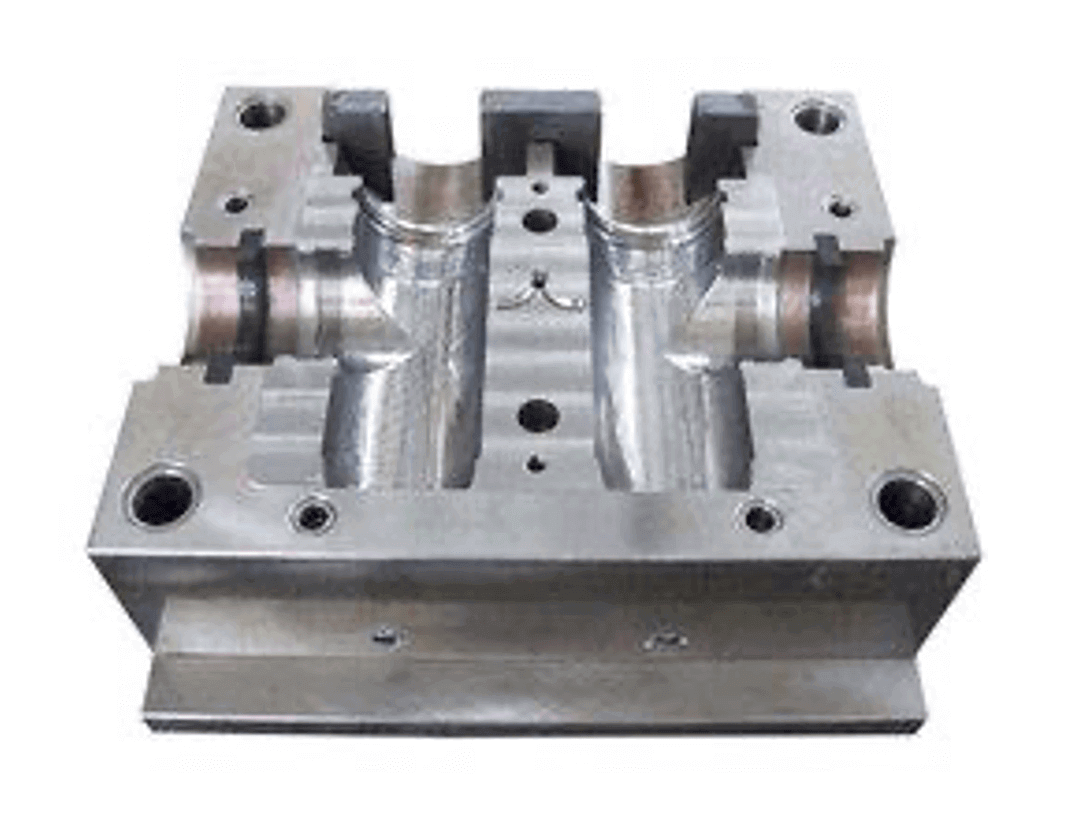

Now stick to what you need to know before buying a pipe fitting mould. ”The material” that the pipe fitting mould is made from is also significant to consider. To create a good quality pipe fitting, the mould must be made from a durable material that can withstand high temperatures and pressures. The most common materials used for pipe fitting moulds are metals, such as steel and aluminum.

Why steel is preferred is because it is solid and durable. It can withstand high temperatures and pressures, making it the perfect choice for industrial applications. Aluminum is also a popular material for pipe fitting moulds because it is lightweight and corrosion-resistant. It is ideal for applications requiring a high level of accuracy, such as aerospace and automotive applications.

The cavity of the mould is also essential. The cavity is the space inside the mould that the metal is poured into. It must be designed in such a way that it produces a high-quality pipe fitting. Some of the most important factors to consider when creating the cavity are the type of metal used, the size and shape of the fitting, and the type of forging or extrusion process used.

Now it’s time to explore market manufacturers of pipe fitting moulds. There are many companies that manufacture pipe fitting moulds, but not all of them are created equal. When choosing a manufacturer, it is crucial to consider the quality of their products, the level of customer service they offer, and the price of their products.

When looking for a quality pipe fitting mould manufacturer, GO4 Mould is a name that you can trust. GO4 Mould is a company that specializes in the manufacture of high-quality pipe fitting moulds. They offer various products, including Plastic Pallet moulds, custom plastic injection moulds, etc. They also offer a wide range of plastic injection moulding services, including abs plastic moulding, polypropylene injection molding, aluminum guttering, and more.

Their products are made from the highest quality materials, using the latest technology, And their customer service is second to none. They are committed to providing their customers with the best possible experience, and are always available to help with any questions or concerns you may have.

In addition, GO4 Mould also bids competitive pricing, making them an excellent choice for your next pipe fitting mould purchase. The certification of ISO 9001:2008 assures the quality and reliability of products. Like parker fittings which is the worldwide leader in innovative hose, tube fitting and adapter technology. So while deciding on buying a pipe fitting mould, GO4 Mould is a name you can bank upon.