What Is the Best Medium Voltage Cable?

Medium voltage cable is famously known in the usage of electrical engineering for a voltage between 1000V and perhaps 33kV. Hence, the best MV cable relies heavily on sizes, standards, materials, custom designs, and installation. For example, our medium voltage cable sizes are available from the lowest. This is from 10kV, up to the highest, which is 33kV.

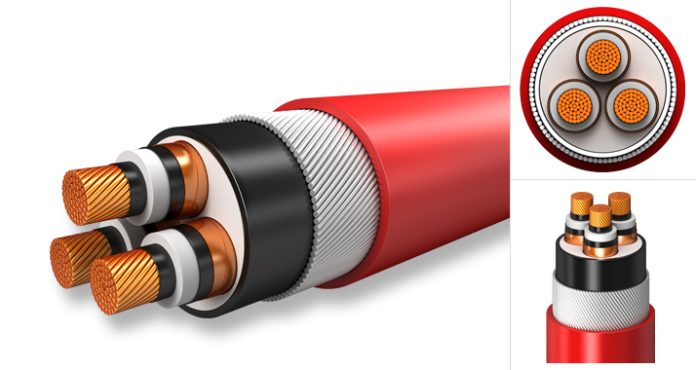

Considering the term “the best medium voltage cable is similar to the MV cable classification. The power cable depends on materials such as copper, cross-linked polyethylene, aluminum, screen copper wires, etc. The combination of how various materials have been put together is what matters to determine the best electric power.

How To Choose the Right Type of MV Cable

There are numerous considerations to make when choosing the proper MV cable type. They start all the way from construction, materials, and standards. The most prevalent types of these options are single core, single core triplex, and three core vital ones.

It is essential to define and focus on the picking method. This helps you choose the correct types of MV cables, high voltage cables, power grids, and transmission lines. You can choose a power cable or leads with or without connectors and conductors.

The ones without connectors will need a banana connector to avoid risking lives. So, connecting bare wire ends to various industrial areas is not advisable.

Aside from that, the following three things are vital in choosing the right type of medium voltage cable:

- Standards and materials

- The length (short or long)

- The terrestrial area because of the installation process.

Where Are Medium Voltage Cables Used?

Electrical cables are usually used for multiple purposes to enhance smooth service to networks and energy/ power. The same applies to MV cables, whereby a transmission line network serves to impart a realm with electrical energy. These medium voltages are utilized in building installations and other high-voltage power grids.

Besides, these medium voltage power cables are not advisable for inter-regional electricity switches. They apply to large facilities and places like industries, natatoriums, hospitals, and large radio masts. These require lead links with transforming stations.

Tramline energy relies on MV cables to supply 10-30 kV. Also, large systems like winches and pallets fall into the trap of medium voltage power furnish. This is due to the additional energy demands everywhere in this era.

The increase comes from the moving parts that need electrical vitality. For this reason, MV cables are required to be strongly outlined for immortality and higher motion potency.

Medium Voltage Construction and Making

Materials and structural design are important when building and producing medium voltage cables. It requires important tools for the MV power cable to be complete and ready for service. In this case, electrical cables shall be sheathed, 10–15kV cross-linked, segregated copper conductor lines having the below helpful traits:

Conductor: It is supposed to include plain round compressed copper conductor to international electronic commission IEC 228 Class 2.

A conductor screen carries an ejected, partly conveyed amalgam or layer.

Insulation: It involves Cross-linked Polyethylene (XLPE) or Ethylene Propylene Rubber (EPR).

Water blocking longitudinal that deals with bulgy powder.

Insulation screens the metallic and non-metallic parts: The metallic one has copper tapes of approximate thickness. On the other hand, non-metallic parts with black lead layered shields or semi conductive materials.

Standards For Medium-Voltage Cables

Medium voltage cables standards differ for various reasons. But most importantly is to understand how they come by. From our focus, there are standards that talk more about MV power cables, like:

The industry particularly deals with the network rail NR/PS/ELP/00008 standard for trackside power cables. These ones include graphite-coated MDPE scabbards for 19/33kV and 25/44kV lines.

The distribution cables have a nominal voltage of 3.6-36kV under DIN VDE 0276 Part 620 standards.

The Installation & Fixing of MV Cables

The installation of MV cables relies hugely on construction materials. Even so, it’s crucial that the cables you choose are optimized to meet the installation’s long lifespan requirements. This one is all about structuring, designing, and manufacturing.

Regarding fixing and causing a distraction to power bestow, add-on collapse is prospective, not safe, or secure. It is more so in public and open sections such as walking paths, holes, or under roads.

Fixing requires one to repair cables that have been destroyed due to multiple purposes. For instance, a breakdown and arcing in a cable joint inserted in a manhole under a footwalk path.

For some reason, this might have occurred due to poor installation of MV cables, possibly resulting in accessory failure. This simply means fixing or repairing will incur other expenses when installation is poorly done. But all the same, it’s critical to undertake both installation and repair seriously. Just like how our team of experts does guide us.

What Are the Testing Facilities for MV Cables?

The main goal of MV cable testing facilities is to inspect and evaluate the rates, components, and wire cable cohesion. So, given the important identity of the economic development link fabricated with power cables, standards, adherence, and authenticity are imperative.

We put our medium voltage cables through various tests in our reputable facility. To ensure they can withstand challenges from users and electrical engineers. This facility tests lead rate voltages of 3.3 kV and higher. These tests include the transmission wire uprightness to check if there’s any fall in the shielding material.

However, in order to obtain a certified and qualified medium voltage cable, they must be tested using all the necessary equipment. ZW cable experts can test every backup premier cable. This is done using a DC electromotive force hype apparatus and a computerized volt pattern. The test should follow the correct processes like segregation, refusal try-out, and other vital ones.

It will still be delivered if it’s an urgent requirement. Straight from stock, produced, or executed on the same day of order.

Regulatory Compliance for MV Cables

Regulatory compliance for medium voltage cable is among many essentials to consider. It is so because it allows you to identify early in the specification procedure. That is, if the regulatory need, like CPR compliance, applies to the cables you choose.

This may bring a change and brilliantly impact the choice of construction, design, and materials used. In addition, it will again assist customers and users in understanding if the power cable is used internally or externally.

It is crucial to where installation takes place for the availability of at least the minimum CPR class achievable. However, there are CPR compliant MV cables sheathed in PVC and LSZH materials. These ones carry up to CPR class Cca and meet relevant standards, which handle up to third-party approval.

You only need to make early communication and give your specifications to us, and we will serve you. Our company is the best. We provide the well-manufactured transmission or MV cable that meets your desires, plus a guide on the installation process.

Disclaimer: This article contains sponsored marketing content. It is intended for promotional purposes and should not be considered as an endorsement or recommendation by our website. Readers are encouraged to conduct their own research and exercise their own judgment before making any decisions based on the information provided in this article.