Europe and the UK are undergoing an energy revolution as new sustainable technologies enable a fundamental transition away from traditional fossil fuels. One of the key technologies at the heart of the shift to clean and renewable energy use is LFP (lithium iron phosphate) batteries.

This article will give a broad overview of LFP battery technology and its role in the future of Europe’s transition to clean energy. It will also focus on how a global specialty minerals company, ICL Group, is investing in the future of European energy and creating a new high tech manufacturing center for lithium iron phosphate (LFP) cathode active material (CAM).

A Quick Insight into LFP Battery Technology

Energy storage has always been the achilles heel of green energy grids that utilize renewable energy sources like solar, wind and tidal energy. It’s relatively simple to generate electricity with photovoltaic panels or wind turbines, but natural energy sources are intermittent. As soon as the sun stops shining or the wind drops, the flow of energy dries up. A traditional coal burning power station can generate energy on demand – 24 hours a day – simply by burning more fuel.

Manufacturers of electric vehicles previously faced a similar energy storage problem. It’s a simple matter to fill a fuel tank with diesel or gasoline and power a car, but it is a lot more complicated to devise a safe and cost effective battery-based power solution for an electric vehicle. Recent advances in battery technologies are delivering innovative energy storage solutions both for hybrid clean energy grids and for a new generation of electric vehicles.

LFP Batteries vs NMC and NCA Batteries

There’s no need for a detailed scientific analysis of battery technologies in this article, but it’s helpful to understand the basics. Any battery has an anode and a cathode. LFP batteries use lithium iron phosphate ((LiFePO4) as the cathode material and a graphitic carbon electrode with a metallic backing as the anode. LFP batteries are rapidly emerging as an environmentally-friendly alternative to NMC batteries that use nickel manganese cobalt oxides, and NCA batteries that use nickel cobalt aluminium materials.

A significant advantage of LFP batteries is that the key materials (iron and phosphate) are abundant in the Earth’s crust and are easy to extract. They do not contain nickel or cobalt which are far less abundant and far more expensive. Although NMC and NCA batteries currently offer some performance advantages over LFP batteries, they can’t compete in terms of cost, longevity and safety (fire resistance and low toxicity).

Europe’s Emerging LFP Battery Market

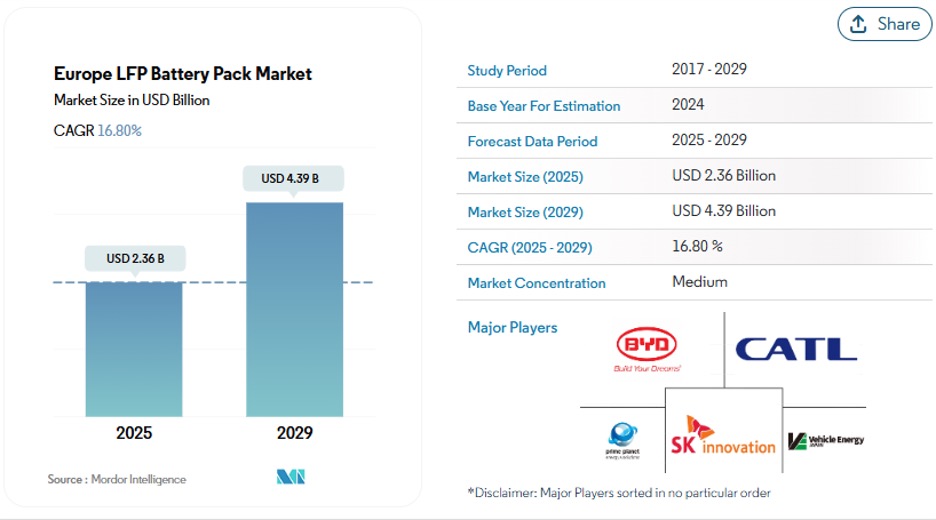

The European LFP battery market is predicted to grow exponentially over the coming decade. Analysts at MordorIntelligence anticipate that by 2029 the market will be worth $4.29 billion, representing a CAGR of 16.8%. Even by the standards of the high tech sector, this is an impressive growth rate. The population of the EU is approaching the 450 million level (and this figure does not include the UK, Switzerland and Norway, or various peripheral markets that are close EU trading partners). As the continent transitions to clean energy and electric vehicles, major LFP battery manufacturers appear to be confident of sustained long-term demand.

To quote Isaac Chan, a partner in Roland Berger ’s automotive practice:

“Automotive OEMs are increasing their usage of LFP to improve the economic competitiveness of EVs. For example, in Europe the LFP share of lithium-ion batteries will more than double to reach 35% by 2030.”

The Expansion of the European LFP Battery Manufacturing Base

ICL Group (NYSE: ICL) (TASE: ICL) is a leading global specialty minerals company and one of the ten largest fertilizer manufacturers in the world. The company has access to major phosphate reserves and is an expert in the sustainable extraction, manufacturing and recycling of phosphates for industrial and agricultural applications, including advanced LFP battery materials.

ICL Group is currently building a new $400 million LFP battery materials manufacturing plant in the US. The high tech facility is located at St. Louis, Missouri and is partly funded by the US government. It will establish ICL Group as a key component in the US electric vehicle manufacturing supply chain.

ICL Group is expanding its manufacturing operations to address the European market with the development of a lithium iron phosphate (LFP) cathode active material (CAM) plan in Spain. The new facility will be built at ICL Group’s existing Sallent site just 60 miles from the Port of Barcelona, a major international transport and distribution hub.

The new European venture will be part of a strategic partnership with Shenzhen Dynanonic Co., Ltd. The joint venture will draw upon Dynanonic’s considerable LFP battery production expertise and will leverage ICL’s proven worldwide upstream experience in the production of specialized phosphates.

An initial investment of €285 million has been allocated to the development of the Sallent plant and it represents a major inroad into the lucrative European LFP battery market. It is envisaged that (subject to minor modifications) the ICL share of the Joint Venture will amount to 80%.

Phil Brown is president of the Phosphate Solutions Division of ICL. He emphasised the strategic importance and timing of ICL Group’s penetration of the European market:

“This expansion builds on our strong, existing upstream position in specialty phosphates globally and leverages the strengths of Dynanonic, a leading producer of battery materials, to develop a significant new market for growth. The time is right to make this move, as LFP is a critical solution for the future of Europe’s energy transition. ICL is excited about this potential investment in Spain, and we are extremely enthusiastic about collaborating with Dynanonic – a valued and long-term partner.”

A Positive Sign for the Future of Green Energy and the Environment

The long-term commitment – backed up by major financial investment – of two global companies to the European LFP battery market is a positive development for the future of green energy and environmental protection across the continent. ICL in particular has a track record of successful investments and acquisitions over the last three decades, including its Boulby mining plant in the UK, Danakil plant in Ethiopia, and a number of production plants in the US.

As well as demonstrating clear confidence in the future of the European EV market and the transition to green energy, ICL Group’s recent ESG report sets out its own credentials as an environmentally responsible corporation. The new Sallent site will be designed to align with ICL Group’s commitment to achieve carbon net Zero by 2050 and will draw upon the company’s widespread experience of environmental regeneration and protection of local ecosystems at its other industrial plants around the world. The joint ICL- Dynanonic represents an important investment in sustainable energy solutions for the European market.