Modern manufacturing is evolving rapidly, focusing on speed, efficiency, and sustainability. As product designs become more advanced and the need for speed, quality, and aesthetics rises, engineers and manufacturers are looking for smarter solutions that move past traditional fasteners.

Introducing EVB tape—a groundbreaking bonding technology that brings together strength, flexibility, and design freedom all in one material. Avery Dennison, a leader in adhesive innovation, has created EVB tape, which is quickly becoming a popular choice over traditional mechanical joining methods such as screws, rivets, and welding.

EVB tape is raising the bar in industrial bonding, making assembly lines more efficient and enhancing product aesthetics.

Beyond Bolts and Welds: Why Manufacturers Are Replacing Traditional Fasteners

For many years, mechanical fasteners have been the go-to choice in industrial assembly lines. Screws, bolts, rivets, and welded joints play a crucial role in structural bonding in various fields like automotive, aerospace, electronics, and construction.

As products become more complex and materials get lighter and more diverse, these fastening methods start to show their limitations. Drilling holes might weaken the material’s integrity. Welding creates heat zones that can weaken components or cause warping. Most mechanical connections are easy to see, which can interfere with design aesthetics and require additional steps like post-processing or cosmetic fixes.

That’s where EVB tape comes into play.

Instead of piercing or distorting materials, EVB tape forms a strong bond between surfaces—quickly, neatly, and without being visible. There are no holes. There’s no heat. There will be no compromises.

What Is EVB Tape?

EVB means Elastic Viscous Bonding, and it really is as innovative as it sounds. This advanced adhesive technology features a viscoelastic acrylic foam core that sticks to surfaces and absorbs dynamic stress.

What makes it different from regular adhesives or glue is its dual-action performance. It sticks well to different materials and stays flexible enough to manage movement, vibration, and changes in temperature over time.

The combination of mechanical strength and stress-dissipation makes EVB tape perfect for bonding various materials—like metal to plastic, plastic to glass, or composites to aluminum—without any degradation or mechanical failure.

Clean Bonding with Zero Downtime

One of the great advantages of EVB tape is how clean and quick the application process is.

EVB tape stands out because it doesn’t need curing time, ventilation systems, or special safety gear like liquid adhesives do. It doesn’t require drilling, tapping, or torque tools like rivets or screws do.

This cuts down on setup time and makes the production line simpler. In both manual assembly and robotic automation, workers just peel, apply, and continue with their tasks. No drying required. No need to wait.

In a production setting, where time is money, efficiency can really make a big difference.

The Science Behind the Stick

EVB tape operates on a molecular level to enhance surface contact and manage energy dissipation. The main material, which is a viscoelastic acrylic foam, plays two important roles: it helps with adhesion and reduces vibrations.

When surfaces expand, contract, or shift because of mechanical or environmental forces, the foam compresses and stretches while maintaining its bond. This is particularly useful when connecting materials that have different thermal expansion rates, like attaching a polymer to a stainless steel sheet.

Traditional fasteners can put stress on the joint, but EVB tape is designed to adapt.

The foam core spreads pressure evenly along the whole bond line. This improves the overall quality of the product, particularly for large panels or components that are subjected to vibration, wind, or impact.

Strength That Rivals Rivets

Don’t let the word “tape” mislead you. This isn’t the kind of stuff you’d find in your office drawer.

EVB tape offers lasting structural strength. Certain grades are designed to handle outdoor weather conditions, resist UV exposure, endure temperature changes, and withstand impacts and fatigue similar to automotive standards.

The tape works really well in these conditions, which is why it’s a popular choice in industries that have high demands, such as:

- Automotive manufacturing

- Consumer electronics

- Aerospace interiors

- Appliance and HVAC systems

- Building facades and cladding systems

The mechanical strength of EVB tape has been tested and confirmed. Actually, for a lot of situations, it not only competes with but also exceeds the performance of traditional fasteners.

Aesthetic Freedom Without Compromise

From a design point of view, EVB tape really makes a difference.

Without screws, welds, or hardware to conceal, product teams can design ultra-sleek surfaces without any cosmetic compromises. Joints become smooth and continuous. The panels are still in perfect condition. The bond is not seen—it’s tucked away out of sight, yet it functions just as effectively as any rivet or bracket.

This is particularly crucial in fields where design contributes to the product’s value, like smartphones, wearable technology, high-end appliances, or car interiors.

Avery Dennison really gets this. The company has created a variety of EVB tapes that come in different thicknesses, densities, and flexibility options, allowing designers to select what best suits their vision and application needs.

Efficiency Gains at Every Stage

EVB tape not only makes the product easier to use. It makes the process easier.

The tape can be pre-cut to the right size and shape, which helps reduce variability and speeds up the production process. Automated dispensers and robotic arms can apply tape accurately, ensuring a clean process and eliminating any chance for mistakes.

After application, the bonded parts can be transferred to the next production step right away.

No clamping involved. No need to wait for cooling. No additional handling required.

This makes the workflow smoother, cuts down on energy use, and makes the most of labor, all while enhancing quality control.

Since EVB tape doesn’t need different types of parts, like screws, nuts, and washers, it simplifies inventory and enhances operational efficiency.

Driving Sustainability and Lightweighting

As we move towards greener products and more sustainable manufacturing, EVB tape is a great partner.

Manufacturers can cut down on:

- Material waste

- Tool wear and replacement cycles

- Energy use during assembly

One of the key benefits of EVB tape is that it allows for a lightweight design. It enables secure bonding of lighter materials such as plastics, foams, and composites, eliminating the need for the reinforcements usually necessary with traditional fasteners.

This is a significant achievement in fields such as automotive and aerospace, where saving even a gram can enhance fuel efficiency, extend range, and lower emissions.

Avery Dennison has prioritized this in its research and development efforts. The tape portfolio features formulations that are tailored for lightweight substrates, offer temperature resistance, and ensure long-term durability, even in tough conditions.

Applications Across High-Performance Industries

EVB tape is currently being used widely in various industries. For instance:

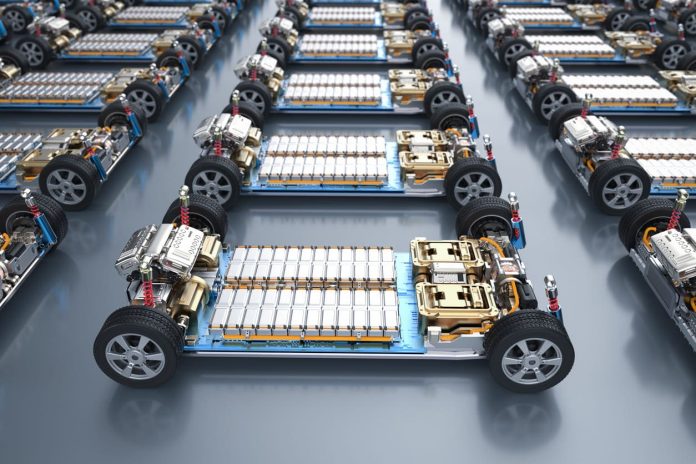

- In automotive EV assembly, the tape is used to secure battery packs, trims, body panels, and lightweight insulation while ensuring safety and avoiding any extra weight.

- In electronics, it’s utilized to secure components within laptops, wearables, and phones, offering shock resistance and heat stability in tight spaces.

- In architecture, it connects panels and signage to building exteriors, standing up to UV exposure and high wind loads while keeping a neat appearance.

These examples show how versatile and reliable the tape is when put to the test in real-world situations.

The Avery Dennison Advantage

The idea of EVB tape is interesting, but how it’s put into practice is important. Avery Dennison really shines in that area.

Avery Dennison is a global leader in adhesive innovation, providing a complete range of EVB tape solutions designed to meet various industrial challenges. They have decades of experience, and their dedication to innovation is only rivaled by the support they provide.

If you’re a manufacturer aiming to boost line speed, a product developer concentrating on design, or an engineer focused on lightweight structures, Avery Dennison has you covered:

- Custom adhesive formulations

- Application engineering support

- Compatibility testing for diverse substrates

- Material certifications and global standards compliance

They collaborate with customers to enhance each stage, starting from the concept all the way to integration.

Future-Proofing Manufacturing with EVB Tape

It’s obvious what the trends are. With the increasing need for quicker production, more efficient assembly methods, and smarter use of materials, EVB tape is set to take the lead.

Its capacity to combine strength, efficiency, and design flexibility makes it an attractive option for the needs of today and the innovations of tomorrow.

EVB tape is showing that you can achieve better bonding without the need for bolts, whether it’s enhancing the range of electric vehicles, making electronics smaller, or streamlining the construction of architectural facades.

Final Thoughts

Today, with speed, design, and sustainability changing the way we think about manufacturing, EVB tape provides a more efficient approach to construction. It takes the place of screws, rivets, and welds—not by settling for less, but by delivering better performance.

As industries change, companies that embrace efficient and clean bonding technologies, such as those created by Avery Dennison, will be at the forefront of innovation, minimize waste, and speed up production timelines.

EVB tape isn’t just an adhesive; it helps with design, improves processes, and supports sustainability.

The question is not about whether you should think about it. So, why haven’t you done it yet?

Disclaimer: This article contains sponsored marketing content. It is intended for promotional purposes and should not be considered as an endorsement or recommendation by our website. Readers are encouraged to conduct their own research and exercise their own judgment before making any decisions based on the information provided in this article.