By Christophe Sempels and Jonas Hoffmann

We have jumped into an era of scarce resources. The related impacts will crescendo in the coming decades but this already raises a clear issue: how to operate in a world where Earth’s resources will have to supply the needs and desires of around nine billion humans by 2050? This question urges companies to rethink business as usual and to find new ways to decouple creation of wealth from the use of resources and energy. There is only one path to ensure such a challenge: innovate. This article introduces why and how sustainable business model innovation can be a great driver of value creation and how it may reorient growth toward a desirable future.1 More specifically, three ideas are presented to instigate leaders to become actors of such innovations: eco-efficiency, circular economy and the transition from a good-centered logic to service-oriented one (see Figure 1).

A Strong Need for Business Model Innovation

The business model being the process of value creation, distribution and capture, it is at this stage that sustainability can fully uncover its value creation potential for a company.

Because business models are designed in a volume-based approach most of the time, they are simply unsuited to integrate sustainability in order to create value. How can an energy supplier, whose income relies on a volume of sales of kWh or m3 of gas, encourage the overall reduction of energy consumption without sawing the branch on which it sits? How can a car manufacturer drastically reduce its steel consumption while generating its turnover by the volume of cars sold? In these situations, the business model does not allow financial and environmental performance to converge naturally and synergistically. Similarly, how can a lively industrial fabric be maintained in developed economies while it is possible to produce it at a much lower cost in developing economies? How can companies be encouraged to favor quality ingredients or sustainable raw materials when, in these times of crisis, cost reduction is on everyone’s lips?

[ms-protect-content id=”9932″]There are relatively few answers to all these questions. If the business model cannot align economic, environmental and social issues, the only credible solution is to change it. This is obviously the goal of this article: providing the first insights to these questions.

Eco-efficiency

Eco-efficiency refers to ‘the effectiveness with which natural resources (mineral, energy and biological) are used by the industrial systems of production and consumption to meet human beings’ needs, at competitive prices, while reducing environmental consequences. It aims to gradually reduce the environmental impact and the quantity of the natural resources used throughout the life cycle of products and services, in order to reach a level in harmony with the earth’s capacity for self-renewal’.2

As an example, the textile industry is known for its heavy water footprint, from the cotton production throughout the manufacture of the end product. Levi Strauss Co. was the first to tackle this issue by analysing the water consumption of the whole lifecycle of Levi’s 501 jeans: 3000 liters of water were used to manufacture a pair of jeans, 55 percent being connected to the Levi supply chain with the remaining 45 percent linked to the laundry of the jeans after purchase. To decrease this volume, water consumption was systematically measured and Levi’s decided to reduce its water footprint in two areas: in its supply chain and among consumers, by creating initiatives for more efficient water use. Efforts paid off. By 2011, the company had achieved average water savings of 28 percent compared to the initial benchmark, with up to 96 percent water savings on certain models (= a saving of more than 16 million liters of water during spring 2011 alone). All these savings were achieved without affecting the aesthetic and functional qualities of the jeans.

The eco-efficiency principle naturally applies to both products and services, but also to processes. Its application is based on some key specifications:3

• Be adapted to its use, form following function: the design should be at the service of the function of the object in order to improve usability and use efficiency

• Reduce the material intensity and minimise the use of nonrenewable resources (raw materials and energy)

• Reduce the energy intensity

• Minimise the toxic components or replace them whenever possible

• Be reliable and useful, and designed to last

• Be easy to maintain, repair and support recyclability

• Minimise its environmental impact on the whole life cycle

Circular Economy: Transforming a Waste into a Productive Resource

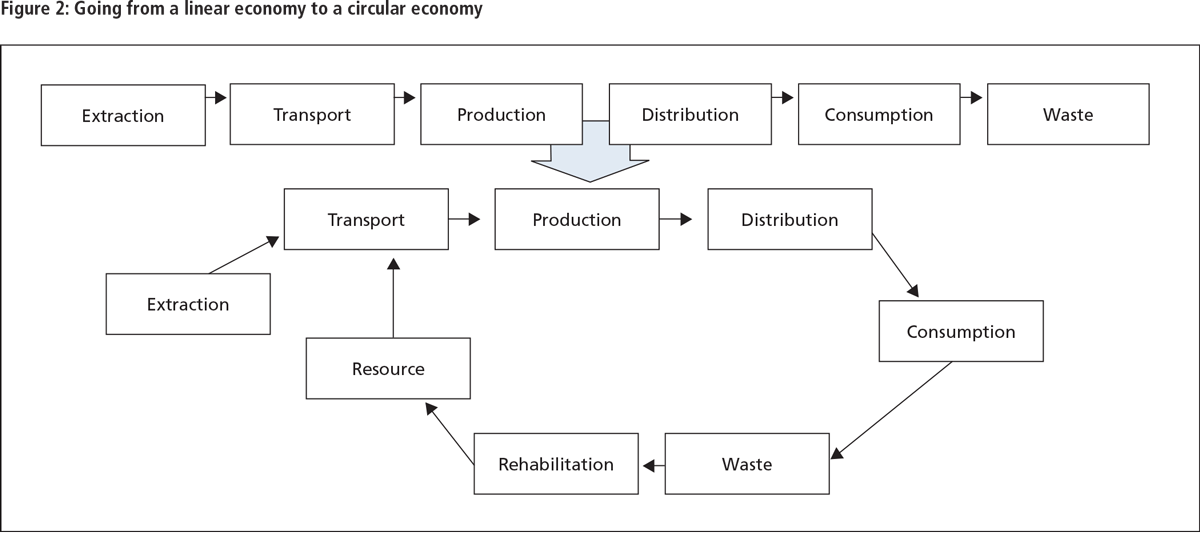

The great majority of our economic models are structured around linear flows of materials (figure 2). When resources become rare, and thus expensive, the price of energy increases and so does the degradation of the biosphere. When the generation of waste results in increasingly intolerable environmental and social issues, the model is unacceptable in all its dimensions, even one based on a traditional economic plan.

The ‘circular economy’ is a new industrial system that replaces the ‘end-of-life’ concept by restoration and regeneration through intention and design.4 By redesigning products, services or processes, it transforms a waste or previously unvalorised resource into a productive one that may be reused in closed-loop systems.

The cradle-to-cradleTM philosophy – based on the circular economy principle – classifies all materials used in production processes around two kinds of metabolism, the biological and the technical. The ‘biological nutrient’ is a material or a product initially designed to re-integrate the natural cycle at the end of its life, being 100% biodegradable. A natural cotton T-shirt could be manufactured with such logic, so that once damaged, it could be composted as natural biological nutrient (reproduction of a natural cycle). By contrast, the ‘technical nutrient’ is a non biodegradable material that can be recovered and reintroduced into a closed-loop production cycle, without loss of quality. Xerox develops machines with this logic, the components of old machines being recovered to be reintroduced in the manufacture of new generations of machines.

The implementation of such logic calls for drastic change in many business blocks of the business model. The value proposition should be adapted in a way that differentiates biological nutrients from technical ones, requiring strong R&D capabilities. The close-loop system implies the implementation of a reverse logistic system that redefines the relationship with supply chain partners and potentially adds new partners. The production should first disassemble and recuperate valuable raw materials that once refurbished are introduced into new economic cycles. The cost and revenue streams are profoundly impacted, with new costs appearing while many financial savings are obtained.

From Product to Service

If circular economy does make business sense, its implementation on a large scale is not straightforward. It necessitates that flows of material would have to be controlled more efficiently. However, when ownership of the product is transferred to the customer, he/she is the one in charge of the product at the end of its life. And despite public awareness campaigns, recycling behavior remains limited. Moreover, the business model is still volume-based.

This transition toward what is called functional economy explicitly pursues environmental (and sometimes social) improvements. To reach such improvements, two configurations should be differentiated: the use-oriented services and the result-based integrated solution.

From Products to Use-oriented Services

Use-oriented services aim to redefine our relation with the tangible goods that surround us by making them available without transfer of ownership, and by invoicing their use. The examples of such services are numerous: hiring, leasing, pooling, shared consumption like car sharing or self-service bicycles, public transport, collaborative consumption, and so on. They do not have the same sustainability potential but the macro-economic consequences may potentially be impressive.

The relation to the physical asset is as such modified. An asset that is shared among several users rather than one alone increases its intensity or optimisation of use. While a personal vehicle spends more than 95 percent of its lifetime in a car park, a shared car will be able to spend from 45 to 55 percent of its life in service, thus increasing the service rendered for the same amount of physical material in use.

The absence of transfer of ownership offers another significant benefit. The company keeps control of the material and can thus organise a closed loop system according to an optimised scheme. The implementation of the principle of circularity is simplified, because the company knows exactly how much material is in use, can plan its return and can therefore control the production planning.

It is therefore not the shift toward use-oriented services in itself that generates sustainable benefits, but rather the related incentives to engage in eco-design and circular economy, coupled with potential improvement due to usage optimisation.

The well-known example of Xerox illustrates such gains. By shifting from sales of copiers to their provision via a leasing system, Xerox has totally redesigned their machines so that 70% to 90% of the components from old copiers can now be recuperated and reused in a new generation of machines. This represents huge financial savings – up to $2 billion in 10 years – coupled with important savings in energy and in raw materials consumption.

If this transition is easy to grasp in mind, its implementation is not. Many social science disciplines have demonstrated the intrinsic value to own. If the B2B markets have a long tradition of outsourcing and ‘make or buy’, it is not the same story in B2C. Marketing thus plays a crucial role in educating consumers of the associated benefits of such a transition. Moreover, the financial dimension of the business model is totally revised. Financial value is not captured anymore in a one-shot transaction but rather in a long term scheme, cash flow being first negative. If the model is in general more profitable, it does require increased capital availability. The value chain is profoundly impacted, including the relationship with customers and the need for partners. Additional activities and resources must be deployed. New segments may appear, such as low-income consumers that cannot afford to buy but could support a monthly fee. The shift in the business model is thus significant.

From Products to Result-based Integrated Solutions

Although use-oriented services may provide a strategic answer enabling an evolution of the business model, they are not suited in all contexts. For fast moving consumer goods or commodities, for example, this transition does not make much sense or, at least, it does not seem to be a natural one. A water supplier provides a volume of water associated with a certain consumption level. The invoicing unit is clearly the use of water and any potential rationalisation of the use would generate a destruction of value for these companies.

Being disruptive by essence, the shift from product to result-based integrated solutions means not selling goods anymore, nor focusing on the usage of goods, but the result. Just think of the case of a company selling pesticide to farmers. What the farmer is seeking in reality is not the product per se, but a way to protect his crops. Just imagine that this company suggests that rather than sell him pesticide, they offer an integrated service of crop protection, invoiced either on the number of acres being protected or on a maximum acceptable loss rate on the crops. The pesticide that could potentially be used in the solution is not a driver of revenue anymore, but now a cost that should be minimised. Better, alternative strategies can be developed in an integral crop protection approach, where several options are employed (new farming practices limiting risks, prophylactic measures, biological fight, and so on), chemical products being the last resort option.

Commercially, the difference is enormous. For the service provider, the complexity increases, but the capacity to deploy an integrated and optimised solution articulated around a service rate confers a decisive competitive advantage, when differentiation at the product level is increasingly difficult to reach. Moreover, by decoupling the revenue from a product volume, it is possible to create a true rupture as regards to the value curve.

In such a scenario, the rupture is total as the scope of the activities is likely to change. By passing from a model of pesticide sales to a model of an integrated solution offering a maximum acceptable crop loss rate, a company needs not only chemical and agronomic competences, but also biological, entomological, hydrological, and so on. It is thus a totally new business model.

Conclusion

When questioning the impact of sustainable development on business, challenges are numerous and tremendous. Some may be afraid, even paralysed by the apparent complexity. The good news is that some paths already exist and may guide innovative leaders or entrepreneurs to design true sustainable business models that conciliate economic performance with environmental and social ones. The path is not easy and progressing through eco-efficiency, circular economy, use-oriented services and result-based integrated solutions, the rupture increases. For sure, there are risks involved, but what a prize to win. Some visionary pioneers have already engaged in such a venture, demonstrating sustainable development’s relevance and rewards.

About the Authors

Dr. Christophe Sempels is Associate Professor of Sustainable Development and Strategy at SKEMA Business School. He has been invited as guest speaker in many universities, business schools and institutions in Europe, in the US and in China. Author of several books on sustainable development, he’s a recognised expert in business model innovation, collaborating with many CEO’s and top managers of companies and institutions to help them integrating sustainability in their core strategy.

Dr. Jonas Hoffmann is Associate Professor of Marketing at SKEMA Business School. He is the co-author of Sustainable Innovation Strategy (Palgrave-Macmillan). He is an emerging markets, innovation and luxury expert giving executive training and consulting in Europe, the US, China and Brazil.

References

1. This article is based on Sempels, C. and Hoffmann, J. (2013), Sustainable Innovation Strategy: Creating Value in a World of Finite Resources, Palgrave Macmillan, London. Interested readers should refer to the book for full details, numerous examples and business cases on the ideas developed in this article.

2. Definition from the World Business Council for Sustainable Development (http://www.wbcsd.org/home.aspx).

3. See Sempels, C. et Vandercammen, M. (2009), Oser le marketing durable : concilier marketing et développement durable, Paris: Pearson, and the World Business Council for Sustainable Development.

4. Ellen MacArthur Foundation (2012), Towards the Circular Economy: Economic and business rationale for an accelerated transition, p. 15, available at http://www.thecirculareconomy.org/ accessed on 31 October 2012.

[/ms-protect-content]

![“Does Everyone Hear Me OK?”: How to Lead Virtual Teams Effectively iStock-1438575049 (1) [Converted]](https://www.europeanbusinessreview.com/wp-content/uploads/2024/11/iStock-1438575049-1-Converted-218x150.jpg)

![“Does Everyone Hear Me OK?”: How to Lead Virtual Teams Effectively iStock-1438575049 (1) [Converted]](https://www.europeanbusinessreview.com/wp-content/uploads/2024/11/iStock-1438575049-1-Converted-100x70.jpg)