By Karin Bursa

Supply chains are overflowing with data, and even the most advanced organizations struggle to keep up with the ever-accelerating flow of information. So what is the solution? Karin Bursa, Vice President at Logility, discusses the value of analytics in keeping companies ahead of the supply chain curve.

According to Google’s Eric Schmidt, there is an estimated 5 million terabytes of data on the internet, of which Google has only been able to index 0.004 percent. Your personal sliver of that minute fraction comes to you via smartphones, tablets and computers. You may have a dashboard on your PC, along with notifications chiming from apps on your phone and tablet. We have come to rely on these indispensable systems to help us manage our lives, to parse through our slice of the information available. However, both dashboards and notification systems have two qualities in common: they are reactive and do not help us plan for what lies ahead.

Today’s supply chain is a crucial element of business. The supply chain has a seat in the board room and the percentage of supply chain executives reporting directly to the CEO has doubled in recent years. An effective supply chain is seen as a competitive differentiator, helping companies launch new products and enter new markets. Responsible for balancing working capital and service levels, the supply chain can literally make or break a company. While supply chain planning systems are forward looking, today’s supply chain teams are reliant upon reactive notifications that present what has already happened.

Structured and Unstructured Data Hit the Supply Chain

Supply chains are overflowing with data. Structured data emerges from information generated by enterprise resource planning (ERP), supply chain planning, point-of-sale (POS), order management, or warehouse management systems. As favourable as these sources are, even the most advanced supply chain organizations still struggle to keep up with and make sense of the ever-accelerating flow of information.

When we add new, unstructured sources to the mix – private social networks such as Yammer and SharePoint, public networks such as Facebook, Google+, LinkedIn, and Twitter – we add a massive amount of new data that shapes or conveys buying intentions, provides clues to upcoming trends, and enables a more connected sales force to better predict the timing of orders and cancellations.

All this timely information can help supply chain organizations tune demand and supply plans, finalize manufacturing plans, and support new product introductions, but it demands a vigilant focus on supply chain metrics and analytics. Drawing on structured and unstructured data, supply chain analytics can deliver rapid insights that help companies identify trends, potential disruptions and new competitive threats. This is the crucial ability to both report what has happened and predict what is likely to occur.

Beyond The Supply Chain Control Tower

Only a few years ago, state-of-the-art best practice was to establish a centralized location, a supply chain Control Tower, where one could assess current supply chain status using KPIs and alerts to focus resources on important issues to resolve. Today, analytics need to be a part of every step of supply chain planning. Analytics need to be everywhere – spanning echelons, encompassing historic, current and future time horizons. Planners need to visualize their plans over time and understand how they relate to the goals established for the business, product family, geography, channel, etc., day in and day out.

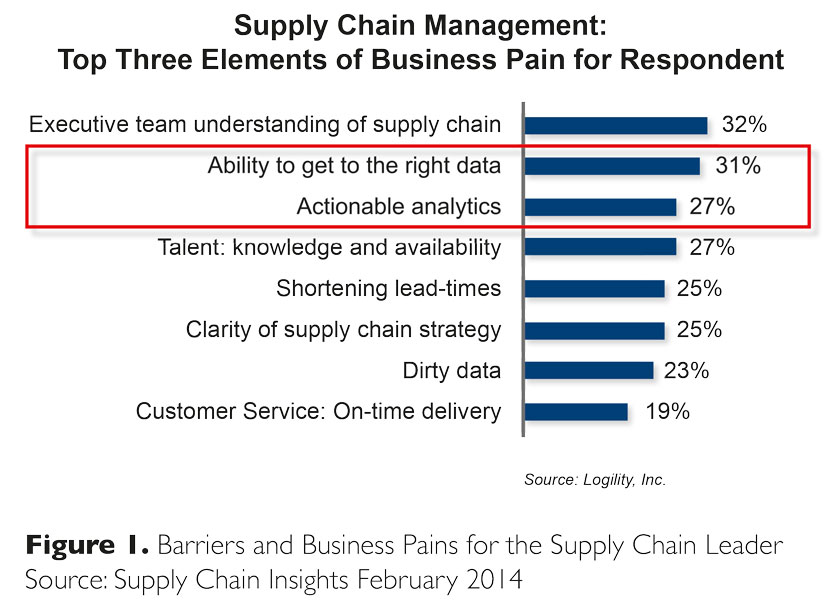

Supply Chain Insights’ report, “Voice of the Supply Chain Leader 2014,” highlights the evolving nature of analytics. According to this research, access to the right data and access to actionable analytics (Figure 1) are two of the top pain points facing today’s supply chain organizations. The report also highlights the lack of ability to pair predictive analytics with visualizationto drive more informed decision-making. Visualization delivers powerful capabilities to supply chain planners including the ability to view the plan in the context of multiple factors, quickly see how the plan could change and where potential bottlenecks may occur to reaching goals and objectives.

Looking into their crystal ball, the same executives pointed to data visualization and increased supply chain visibility as two of the top trends impacting operations. As valuable as the Control Tower concept is, advanced systems need to go beyond, making sense of the data and delivering the information planners require in the context of their role within the supply chain.

Planners may log into the system and check their dashboards; this is a great place to start the day and get an overview. The next step is to gain insight into what has occurred as well as what will happen today, tomorrow or six months from now.

What If?

What would happen if you change suppliers or move manufacturing from China to India? How would you react to a natural disaster or a new competitor launching in your category? These are questions you face every day, questions that require answers. The traditional scenario planning cycles of once a quarter or worse, once a year, are not good enough in today’s market. Actionable analytics that go beyond telling what happened enable rapid scenario planning and the ability to simultaneously compare multiple scenarios. This takes a supply chain from scrambling to reroute production following a change in plan to simply enacting a plan B or C already in the system and shared throughout the network.

According to Supply Chain Insights, only eight percent of companies surveyed are satisfied with their “what-if” scenario planning capabilities. This alarmingly low number shows just how exposed the vast majority of supply chains are to “changes in the plan.”

Social Signals

Social signals from sources like Chatter and Yammer can be used to stay ahead of changing customer preferences. The information can be presented throughout the planning process, incorporated into future views and used for rapid scenario planning. Social collaboration across the enterprise, its customers, and suppliers, allows companies to quickly share the right metrics, identify issues before they escalate and seize new opportunities. Analytics help teams align actions with the goals and objectives of the business.

New Products

The typical cycle of 1 – 2 new product seasons per year has morphed into 3, 4 or even 6 seasons per year depending on the industry. This creates greater reliance on historical sales data to plan for expected demand. It calls for immediate access to what is happening in the supply chain, as well as the ability to automatically visualize what is likely to occur. Rapid access to information combined with the ability to game-plan multiple scenarios can drive better replenishment, effective promotions and longer product life.

Analytics in Action

One company I recently spoke with described their supply chain journey as one of failed notions, spreadsheets and error fixing. Analytics were simply numbers in an Excel file. Little insight could be gleaned, and it was almost impossible to discern actions to be taken or what plans to develop.

The multi-billion dollar company recognized the problem and developed a plan of action to change their processes and technology. They started, as many companies do, with their ERP system. However, this led down the same worn path – the supply chain team found many of the answers they were promised were not available, or had to be custom developed. The company turned to expansive spreadsheets to augment the ERP implementation. This approach led to more time spent seeking out formula and data entry errors than proactively planning the supply chain.

The company turned a corner, though, when it implemented a best-of-breed supply chain solution to manage demand, inventory, manufacturing, and replenishment planning. Besides greater depth and breadth of capabilities, analytics embedded throughout the system delivered the right information to the right user at the right time to drive actionable insights. The supply chain team went from a reactive, error checking process to a proactive planning process that now allows the team to focus on the metrics that matter.

This increased level of insight and supply chain visualization helped the company understand the impact of each decision, delivered greater clarity on actual versus forecast, improved manufacturing throughput by discovering missed capacity, and helped reduce inventory while still meeting service level requirements.

Summary

To stay in front of the market, supply chain teams must do a better job of looking forward and planning ahead. Supply chain analytics goes beyond providing KPIs on what has happened, to help predict what will happen. Analytics minimize guesswork and improve strategic, tactical and operations decision making.

Advanced supply chain analytics utilize sources of structured and unstructured data to deliver rapid insights that help companies identify trends, spot potential disruptions and detect competitive threats in advance. Analytics everywhere is about delivering the right information to the right people whenever and wherever they are.

Does your supply chain team have instant access and visibility to the data that matters across the enterprise, its partners and suppliers? If not, the time has come to go beyond Control Towers and spreadsheets to basing strategic actions on analysis of all the data, all the time.

About the Author

Karin L. Bursa is a vice president at Logility, a provider of collaborative supply chain management solutions. Ms. Bursa has more than 25 years of experience in the development, support and marketing of software solutions to improve and automate enterprise-wide operations. You can follow her industry insights at www.logility.com/blog. For more information, please visit www.logility.com.

![“Does Everyone Hear Me OK?”: How to Lead Virtual Teams Effectively iStock-1438575049 (1) [Converted]](https://www.europeanbusinessreview.com/wp-content/uploads/2024/11/iStock-1438575049-1-Converted-100x70.jpg)