This article will attempt to briefly explain the top seven advantages of CNC machining over conventional machining methods. This is a subject many people are not familiar with — it may be helpful for newbies, but experienced workers might also find some valuable information they weren’t aware of.

First off,

What is CNC Machining?

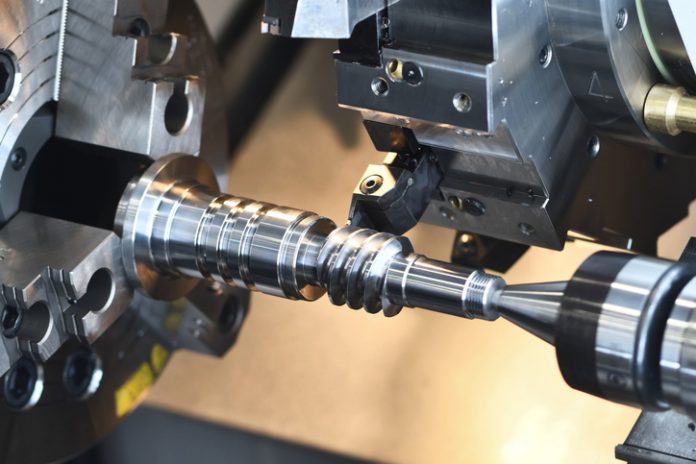

CNC machining is the use of computer numeric control via automated machinery to manipulate raw materials into a final product. These machines usually receive data by computer, either through G-code created manually or CAM (computer-aided manufacturing) software, which auto generates the program for smooth, precise cuts.

CNC material can slightly vary from country to country; within the U.S., a CNC mill is a machine with a bed that can move in two directions along three axes, and a CNC lathe is a rotating spindle with a tool changer.

What is Conventional Machining?

Conventional machining, on the other hand, is done without computer help to guide or monitor the machine. The workpiece is marked with pencil lines that are used as reference points by an operator who moves it manually to guide the cutting tool through precise movements. This requires more effort for precise accuracy compared to CNC machining.

Here are 7 advantages of CNC machining over conventional:

1. Greater Accuracy and Better Finishing

The accuracy of CNC systems is dependent on the type of controller used. If a more accurate positioning system is used for the controller, then better accuracy can be achieved. With conventional machining, the degree of accuracy depends on how well an operator can guide the machine.

After machining is complete, the part needs to go through finishing processes such as grinding and polishing to achieve a smooth surface finish. The accuracy of conventional machining is only as good as the operator guiding it through manual movements.

With CNC systems, there is no need for manual inputs from an operator, so the finished product will always be more accurate. One factor that determines the accuracy of CNC machining is a more accurate positioning system is used for the controller, then better accuracy can be achieved.

2. Quality is more consistent

CNC machines are known for their accuracy and repeatability, which allows for parts to be made quickly and more precisely. This leads to better quality control because the parts produced will be similar in dimensions.

Conventional machining can vary depending on how well an operator uses the machine. As described above, successful conventional machining can be very dependent on the experience of the operator and how skilled they are.

3. Faster production speeds are possible

If a company is producing parts, then using CNC machining instead of conventional cutting will result in faster production times. The more advanced equipment used in CNC machining allows it to produce parts in less time than conventional cutting due to better accuracy and faster feed rates.

4. The use of water or oil-based coolants results in a better quality finish

Using machining methods that are not CNC-based can cause lower accuracy levels because of vibrations present during cutting. Conventional cutting does not allow for the same level of precision as CNC machining because of this vibration.

Conventional cutting can cause the surface finish of a part to be less than ideal, which is not an issue when using CNC machining because it does not result in vibrations and creates a better surface finish.

The use of CNC technology also reduces the need for secondary operations such as polishing, which can be costly and time-consuming.

5. CNC machines can handle more complex designs than conventional cutting tools

CNC machining allows for more complex shapes to be cut into a workpiece than conventional cutting, due to the use of CAM software that incorporates contours and other intersecting elements with ease.

6. Parts can be lighter and stronger with the aid of complex geometry

CNC machining is capable of making parts that are much smaller than would be possible for a conventional machine, thus allowing for the creation of parts that are much lighter and more efficient.

7. CNC machining can produce near-net shapes

One of the main advantages of CNC machining is that it can create near-net shapes in a single operation. This means that little to no additional machining would be required after receiving a part from a CNC mill, making for increased efficiency and faster turnaround time than conventional machining techniques.

Conclusion

There are many advantages of CNC machining over conventional machining. Some of these advantages include greater design freedom, finer features, and higher accuracy. Thanks to its many benefits, it’s no wonder that more and more manufacturers are adopting the process every day.