By Karin Bursa

Do you view inventory as a cost factor, a risk, a service level influencer or a competitive advantage? Many executives view inventory mainly as a cost. In reality, inventory can be a competitive advantage that lowers costs, improves service levels, and helps boost revenue – all at the same time.

Over the past decade, inventory optimization (IO) has moved from a concept discussed in academic forums to a proven strategic weapon that improves corporate profitability. Well documented results include Hewlett Packard’s achieving more than $130 million in total inventory savings1, Microsoft increasing their inventory turns 18-20% while simultaneously increasing fill rates by 6-7%2, and Procter & Gamble’s reduction of inventory levels by $100 million for its beauty division3. These are not isolated incidents. For companies that implement IO, a 10% – 30% reduction in total inventory is common, achieving a major shift in the balance between inventory cost and service level.

Inventory optimization is an advanced scientific approach to understanding and quantifying the propagation of demand and supply uncertainties across a multi-level supply chain. Today it is considered a core competency at both mid-size and Fortune 500 companies in a wide range of industries, and has proven to be a sustainable process that frees up millions in working capital by reducing inventory without negatively impacting service levels. Unlike traditional ‘binge and purge’ cycles of overproduction followed by brute-force reductions, savings are achieved and inventory turns are increased while driving more profit to the bottom line.

[ms-protect-content id=”9932″]

Improving the Trade-off between Inventory Cost and Service Level

While setting formal inventory targets is a best practice, many companies still manage inventory buffers by padding the schedule and holding more inventory at multiple stages of manufacture and distribution than required. For all but the simplest of products, this safety-time approach is inadequate. Another common approach is to establish targets based on rules of thumb. This involves setting a days-of-supply (DOS) coverage target for every item. While DOS rules of thumb are easy to understand, they have three serious consequences. First, DOS is based on average demand and not variability. Second, DOS approaches are forward-looking, whereas inventory targets are actually backward looking since they are an outcome of production decisions made in earlier periods. Third, DOS policies rarely consider the item’s velocity, margin contribution or other important attribute.

Inventory optimization calculations performed within a single supply chain stage are an improvement over rules of thumb, and provide an effective first step toward end-to-end optimization. Often a company’s early IO initiatives will focus on finished goods (FG) only. Success here begins to move the company to a new trade-off curve between inventory cost and service level performance – and opens the door to dramatic further improvement by expanding optimization efforts to encompass WIP and raw materials throughout the end-to-end supply chain.

The Moving Target

Following the initial deployment of IO within a single stage, companies quickly realize the opportunities and benefits associated with taking a strategic approach across multiple echelons of the global supply chain. Multi-echelon inventory optimization (MEIO) delivers great benefits by modeling interactions between all stages of the supply chain and recommending holistic changes to safety stock buffer sizes and locations throughout. MEIO has significantly more freedom since it does not assume, like single stage models do, that a specific location must hold inventory. Modeling multiple stages can incorporate other types of inventory, including cycle stock and prebuild, along with safety stock resulting from time-phased demand signals.

Taking IO to multiple stages encourages the supply chain organization to focus on achieving the same corporate goals as the rest of the organization. Sales, manufacturing, operations and procurement become a more effective team. One global chemical company realized an initial 20% reduction in inventory costs. Multi-echelon inventory optimization allows them to strategically evaluate changes in their global footprint to identify and model production facility requirements and distribution centers. This ongoing view and re-evaluation of the supply chain has led to an additional 17% cost reduction.

Once the supply chain model and financial targets are set, IO provides sensitivity and “what if” analysis to evaluate the pros and cons of different scenarios and business conditions where the cost and service trade-offs of every alternative are clearly defined.

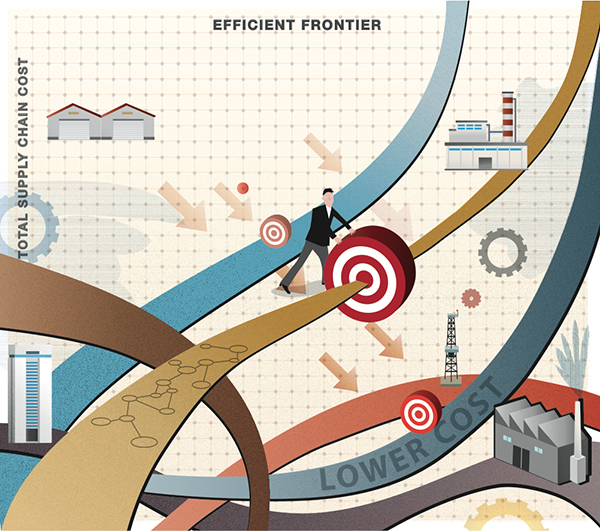

The curve that results from graphing the trade-off between inventory cost and service level is called a supply chain’s “efficiency frontier”. As service level requirements increase, the cost of inventory travels up along this curve. Inventory optimization can move an organization to an entirely new trade-off curve; a better efficiency frontier that produces higher service levels at lower inventory cost than was possible before. [See Figure 1]

You Need a Steering Wheel to Drive Your High Performance Supply Chain

The discipline of multi-echelon inventory optimization is separate and distinct from the value added by enterprise resource planning (ERP) and advanced planning systems (APS). These operational systems do not optimize inventory policies and targets, nor do they provide analytical tools to explore what-if scenarios and evaluate alternative inventory strategies. Transactional systems do not model the complex supply chain, analyze the interdependencies across the entire ecosystem, discover the causes of inventory, and recommend optimal policies and targets. Only the independent discipline of inventory optimization can do this and feed recommendations into the ERP environment.

The true power of IO systems is rooted in analytical methods developed to solve complex decision-making problems, a field of mathematics known as operations research. Treating inventory management as a stochastic process means that its behavior over time is determined both by predictable actions and by less-predictable factors. Inventory optimization algorithms are similar to those used in making financial investment decisions (which should remind us to consider inventory to be an investment seeking a prospective return on sales).

In other words, even if you own a Ferrari of an ERP solution, without inventory optimization, it’s a Ferrari without a steering wheel.

A Mature Discipline for an Uncertain World

In less than a decade, inventory optimization has emerged as a proven technology that dramatically reduces working capital trapped in excess inventory while maintaining or improving customer service levels. In addition to scientifically accounting for the interdependencies of various stages of the supply chain, inventory optimization uniquely mitigates the impact of demand uncertainty as well.

Every supply chain team wishes it had more accurate forecasts, and much energy and effort are expended in pursuit of forecasting perfection, but there will always be a limit to forecasting accuracy as long as there is uncertainty in the demand signal. Here, inventory optimization plays another crucial role by using hard-and-fast historical business data to create a very accurate model of time-phased demand uncertainty stretching far into the future. By creating an envelope of demand over time, the IO system lets planners confidently determine the absolute minimum inventory profile (targets, buffers and placements) necessary to ensure a specific service level, given the degree of uncertainty the business has historically encountered. Even in a hard to forecast environment, this helps planners avoid the universal tendency to overbuild and then overreact by slashing inventory across the board. MEIO techniques keep the business competitive at all phases of the product life cycle and at all twists in marketplace behavior.

Embarking on a solid inventory optimization initiative puts any organization on the path to higher supply chain performance, better business decisions and greater competitiveness. Of course, there is always a trade-off between inventory cost and service level. At any given time, raising the organization’s service level causes an increase in inventory cost. Graphing that trade-off relationship produces a curve that is often called the “Efficient Frontier.” At the core of the MEIO process is the ability to move a company from its current trade-off curve to an entirely new and better curve of higher performance for less cost.

Born from an advanced mathematical discipline for understanding and quantifying stochastic systems with many dependent variables, today’s MEIO can master supply uncertainties across a multi-level supply chain and recommend optimal inventory policies and targets to achieve real-world business goals. A new and better Efficient Frontier awaits you on your inventory optimization journey.

About the authorKarin L. Bursa is vice president of marketing at Logility, a provider of collaborative supply chain management solutions. Ms. Bursa has more than 25 years of experience in the development, support and marketing of software solutions to improve and automate enterprise-wide operations. You can follow her industry insights at www.logility.com/blog.

For more information, please visit www.logility.com.

Notes

1.Billington, C., G. Callioni, B. Crane, J. D. Ruark, J. Unruh Rapp, T. White, and S. P. Willems. 2004. Accelerating the Profitability of Hewlett-Packard’s Supply Chains. Interfaces. 34(1) 59-72.

2.Farasynm I., S. Humair, J. I. Kahn, J. J. Neale, O. Rosen, J. D. Ruark, W. Tarlton, W. Van de Velde, G. Wegryn, and S. P. Willems. 2011. Inventory Optimization at Procter & Gamble: Achieving Real Benefits through User Adoption of Inventory Tools. Interfaces 41(1).

3.Neale, J. J., S. P. Willems. 2009. Managing Inventory in Supply Chains with Nonstationary Demand. Interfaces 39(5) 388-399.

[/ms-protect-content]